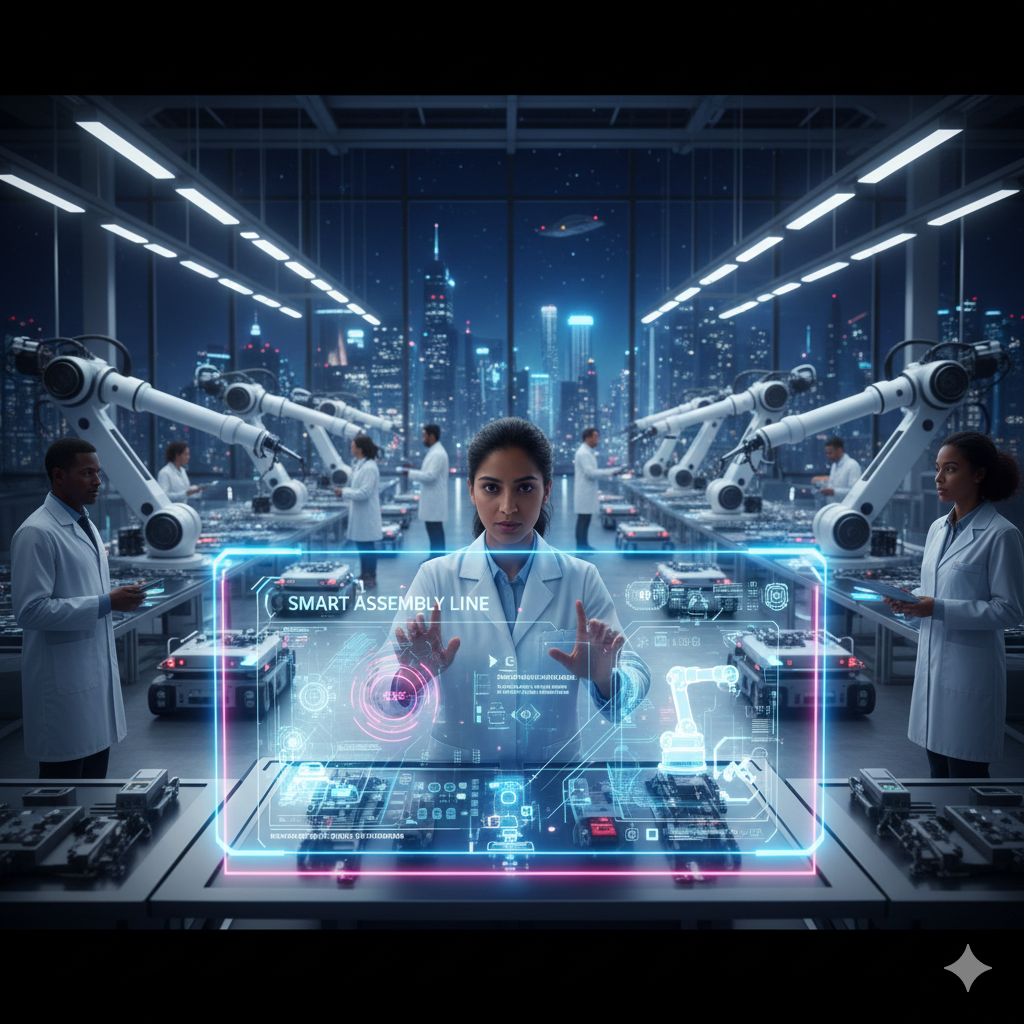

Smart Assembly Lines Using AI and Robotics

Smart Assembly Lines Using AI and Robotics

A considerable revolution is taking place in the industrial landscape as a result of the incorporation of artificial intelligence (AI) and robotics into manufacturing lines. Smart assembly lines are able to improve efficiency, eliminate errors, and optimize production workflows by combining the decision-making capabilities of artificial intelligence with the precision of robotics. These systems enhance efficiency, guarantee quality that is consistent, and enable producers to fulfill the growing demand for personalized products. They accomplish this by automating jobs that are repetitive, monitoring processes in real time, and modifying operations in a dynamic manner.

Optimizing Processes Through the Use of AI

AI is an essential component in the process of optimizing assembly line procedures. Algorithms that learn through machine learning examine huge volumes of operational data, which may include manufacturing speed, component quality, and equipment performance. Through the identification of inefficiencies and patterns, artificial intelligence makes recommendations for adjusting production settings, balancing workloads, and reducing downtime wherever possible. This technique, which is driven by data, enables assembly lines to function at their highest possible efficiency while simultaneously preserving product consistency and cutting down on resource waste.

Robotic Automation for the Purpose of Accuracy and Rapidity

In the field of robotics, the physical capability to carry out tasks that are repetitive, precise, or hazardous with a high degree of accuracy is provided. With minimal assistance from humans, robots driven by artificial intelligence are able to do tasks such as assembling, welding, packaging, and material handling. It is possible for robots to adapt to changes in parts, identify errors during assembly, and make corrections in real time if they are integrated with artificial intelligence. Increasing the speed of production while simultaneously maintaining better quality standards is made possible by the combination of intelligence and mechanical accuracy.

Monitoring of Quality in Real Time

Intelligent assembly lines make use of artificial intelligence and computer vision systems in order to continuously monitor product quality. For the purpose of identifying flaws, alignment faults, or inconsistencies, cameras and sensors are used to check components and assemblies. The data is analyzed by AI algorithms in real time, and any irregularities are identified and flagged immediately. Continuous quality control stops defective products from advancing further along the production process, which cuts down on rework, waste, and operational expenses while simultaneously guaranteeing that customers are satisfied.

Equipment that undergoes Predictive Maintenance

Reliable operation of assembly line machinery is ensured by predictive maintenance that is powered by artificial intelligence. The vibrations, temperature, load, and operating stress measured by sensors are all collected via sensors. Through the use of machine learning models, this information is analyzed to forecast potential failures of equipment before they occur, which enables prompt maintenance interventions. Maintaining uninterrupted production flows, extending the lifespan of machinery, and reducing unscheduled downtime are all benefits that can be achieved with predictive maintenance.

The Customization and Adaptive Workflow Features

AI makes it possible for intelligent assembly lines to adjust to the ever-changing demands of production. Artificial intelligence solutions are able to dynamically change workflows, robot programming, and material handling procedures for manufacturers who produce several product variants or orders that are customized. The capacity to quickly respond to market demand without compromising quality is made possible by this versatility, which also helps to cut setup times and enhance efficiency.

Optimization of Resources and Energy Efficiency as Priorities

Through the analysis of operational data and the modification of equipment utilization in response to workload needs, intelligent assembly lines are able to optimize energy consumption. AI algorithms have the ability to power down gear that is not in use, optimize robot trajectories, and reduce energy expenditures that are not necessary. Additionally, artificial intelligence assists in the efficient management of raw materials, thereby reducing waste and guaranteeing that production processes are both environmentally responsible and cost-effective.

Industrial Internet of Things Integration

It is possible for assembly lines to become fully connected ecosystems through the integration of platforms that are part of the Industrial Internet of Things (IIoT). Through the use of sensors, robots, and artificial intelligence systems, industrial units are able to communicate real-time data, which enables centralized monitoring and control. Because of this connectedness, predictive changes, remote supervision, and extensive reporting are all possible, which results in a manufacturing environment that is both transparent and responsive.

The ongoing pursuit of knowledge and improvement

In intelligent assembly lines, artificial intelligence systems continuously learn from operational data, hence improving decision-making processes over the course of time. The accumulation of experience via adaptive algorithms leads to improvements in production scheduling, defect identification, and resource allocation. Through the process of continuous learning, assembly lines are able to become increasingly more efficient, resilient, and capable of meeting the demands of complex industrial processes.

Through the integration of intelligent decision-making and precision automation, intelligent assembly lines that make use of artificial intelligence and robotics are reshaping modern production. Not only can these systems improve energy efficiency and resource usage, but they also improve process optimization, quality control, predictive maintenance, and adaptive workflow management. Smart assembly lines will become increasingly flexible, efficient, and capable of meeting the needs of high-quality, customized production as artificial intelligence and robotics technologies continue to advance. As a result, they will become an essential component of the technological landscape of the future of industrial manufacturing.